Carbon Digital Light Synthesis™ (Carbon DLS™) 3D printing service

What is Carbon DLS™?

Carbon DLS™ is a resin-based polymer process that uses light and heat to create parts with isotropic properties, complex geometries, and excellent surface finishes. DLS offers a wide range of production-grade materials, allowing engineers to build end-use parts right off the printer. Fast Radius’ Chicago factory is the largest public install-base of Carbon technology in North America.

We are certified in using the Carbon platform from design through production.

Producing parts with Carbon DLS™

| M2 Printer | L1 Printer | |

|---|---|---|

| Build Volume | ~189 x 118 x 326 mm ~7.4 x 4.6 x 12.8 in | ~400 x 250 x 460 mm ~15.7 x 9.8 x 18.1 in |

| Minimum feature size | Material dependent, typically: ~0.25 – 0.5 mm ~0.01 – 0.02 in | Material dependent, typically: ~0.25 – 0.5 mm ~0.01 – 0.02 in |

| Lead time | As low as 3 business days | As low as 3 business days |

| Painting | Smoothing | Press-fit inserts | Bead blasting |

| Digital texturing |

Let’s make your Carbon DLS™ parts.

Right now.

Making disruptive design possible

Steelcase wanted to innovate a high-end office chair with the possibility for mass customization. We helped them make something new and cut 90% of their product development cycle time.

Common Carbon DLS™ applications

Carbon DLS™ is often used for end-use parts because it produces high tolerances and smooth surface finishes. The speed of the Carbon DLS™ 3D printing process makes it an attractive option for rapid prototyping.

High-volume production runs

Cost-effective and quick production of small parts.

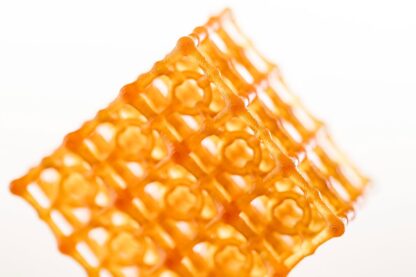

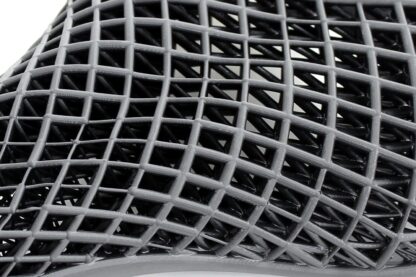

Foam replacement

Elastomeric lattice design enables custom mechanical responses.

Functional prototyping

Durable prototypes suitable for testing in real-world conditions.

Chemical and heat resistant parts

Materials that meet many functional and regulatory requirements.

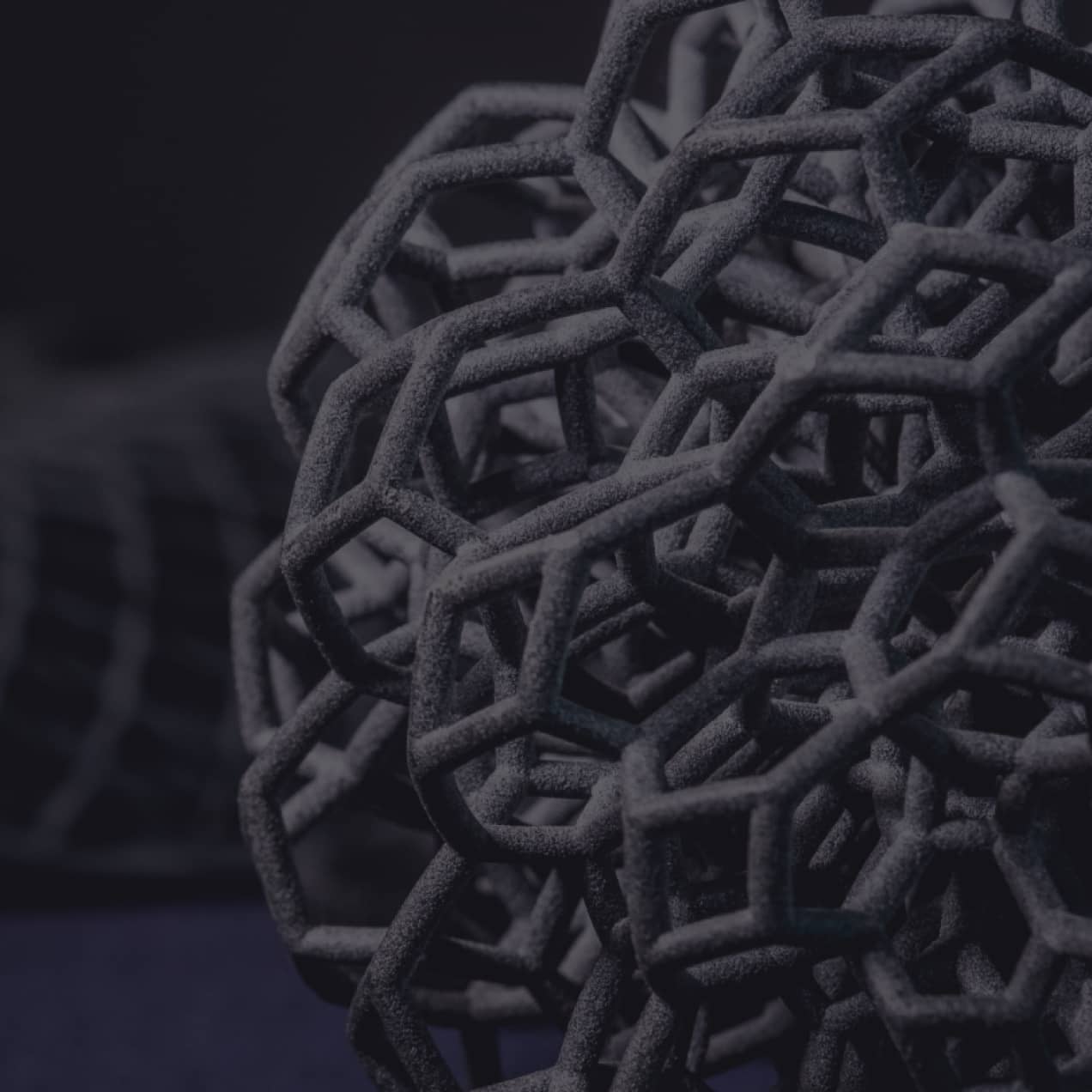

Complex parts

Process allows geometries that would be impossible with other methods.

Fast Radius manufacturing solutions

Fast Radius manufacturing solutions, including 3D printing, are used by businesses across the world. Learn more about our manufacturing capabilities:

3D printing

Fast, scalable, and cost-effective 3D printing technology for a variety of industrial applications.

CNC machining

Precision computer-controlled machining processes, utilizing rotating drills, end mills, and lathes.

Back

Back