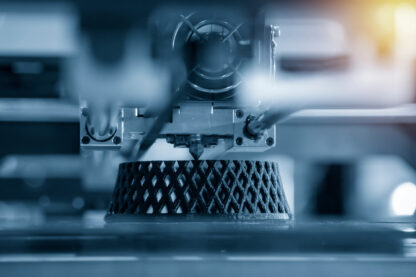

Fused deposition modeling (FDM) 3D printing service

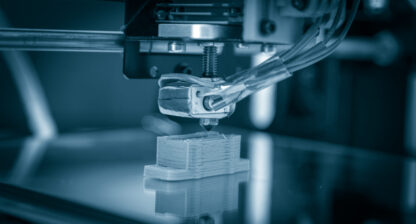

Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF), is the most common type of 3D printing. FDM has short lead times, a relatively low cost per part, and can produce larger parts than many other additive polymer technologies. With a variety of material choices and finishing options, our FDM 3D printing service is ideal for creating everything from quick prototypes to the final product. Our in-house FDM technologies include the Fortus 450mc and the Fortus 900mc.

Producing parts with FDM

| Maximum part size | 914 x 610 x 914 mm 36.0 x 24.0 x 36.0 in |

| Minimum part size | 0.4 mm 0.016 in |

| Lead time | As low as 3 business days |

| Ultem 1010 | PC-ISO | ABS-M30i | Nylon 6 | Antero 800NA |

| Ultem 9085 | PC-ABS | ABS-M30 | Nylon 12 | Antero 840CN03 |

| Ultem 9085 CG | ASA | PPSF | Nylon 12CF | |

| PC-10 | ABS-ESD7 | ST-130 |

| Painting | Heat staked inserts | Bead blasting |

| Helicoil inserts | Sanding |

Let’s make your FDM parts.

Right now.

Common FDM applications

With a variety of material choices and finishing options, FDM 3D printing is ideal for creating everything from quick prototypes to the final product.

Regulatory requirements

Aerospace, food-grade and automotive applications.

Large parts

Larger build size than other additive technologies.

Jigs and fixtures

Practical and reliable tooling.

Prototypes

Quick turnaround allows for rapid iteration.

Fast Radius manufacturing solutions

Fast Radius manufacturing solutions, including 3D printing, are used by businesses across the world. Learn more about our manufacturing capabilities:

3D printing

Fast, scalable, and cost-effective 3D printing technology for a variety of industrial applications.

CNC machining

Precision computer-controlled machining processes, utilizing rotating drills, end mills, and lathes.

Back

Back