CNC machining services for Maryland

Fast, scalable, on-demand CNC machining services for Maryland. Upload your CAD file and take your project to production in days.

Find CNC machining services for Maryland

Maryland is home to thousands of manufacturing businesses, creating products and parts for customers across the US and the world. Supported by cutting-edge technology and a skilled workforce, Maine’s manufacturing output includes aerospace and defence parts, computers and electronics, fabricated metal, medical devices, and more. Make your project possible with Fast Radius CNC machining services for Maine.

Explore our CNC machining services

Computer numerical control (CNC) machining is an automated, subtractive manufacturing process that uses rotating cutting tools such as drills, end mills, and lathes, to remove material from solid workpieces. CNC machining is a cost-effective, precision process capable of creating parts quickly and in large quantities.

Discover Fast Radius CNC machining services for Maryland here:

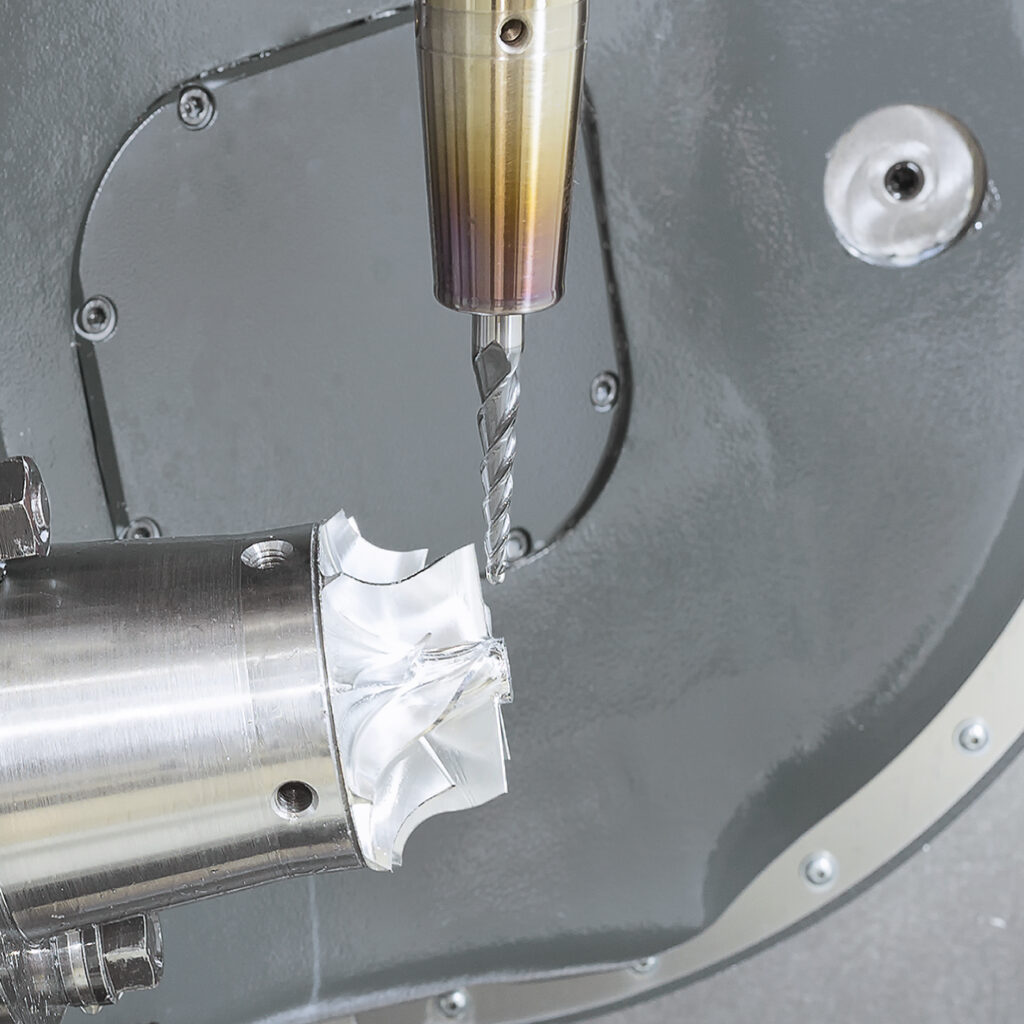

Milling

CNC mills are effective for geometric designs and rapid production requirements. Our CNC capabilities include both 3-axis and 5-axis mills.

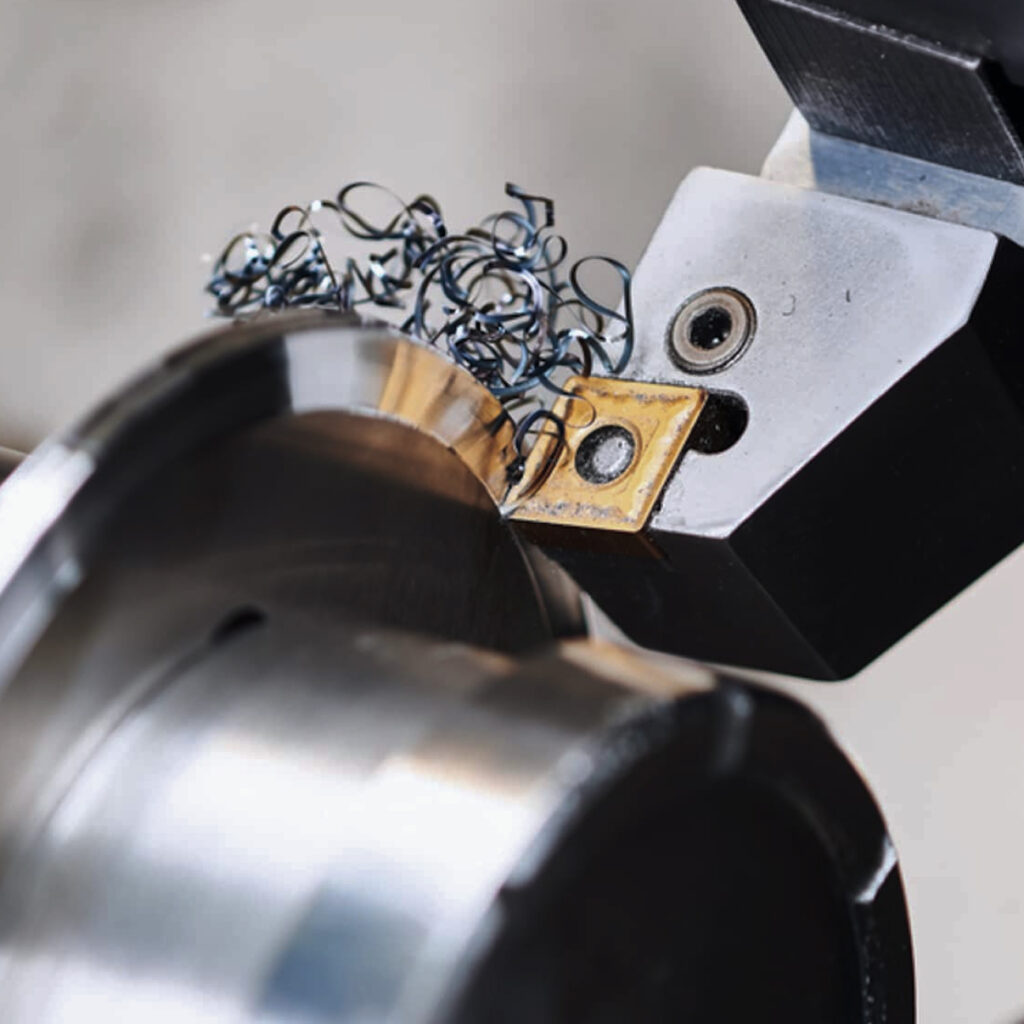

Turning

CNC turning is a process in which an automated lathe shapes a rotating workpiece. Turning is useful for shaping rounded or cylindrical geometries.

CNC machining applications

From single parts to high-volume production runs, CNC machining has a spectrum of industrial applications. Learn more about the key applications of CNC machining here:

Tooling

CNC machining uses a variety of cutting, drilling, and lathing tools to manufacture parts with complicated cuts and angles.

Metal fabrication

CNC machining is a safe, effective way of creating high quality metal parts with exceptional tolerance levels.

Niche manufacturing

CNC machining is capable of creating a range of niche, durable metal and plastic products that alternative manufacturing processes cannot.

Hybrid manufacturing

CNC machining is not just a process for metals: molded and 3D printed parts can also be machined.

Medium-to-high-volume production

CNC machining is particularly useful for medium to high-volume manufacturing runs, offering automated speed and cost benefits.

Rapid prototyping

The CNC machining process is fast, autonomous, and useful for the production of prototype parts.

Why choose CNC machining?

CNC machining is a flexible, cost-effective manufacturing process with significant productivity benefits. Get in touch with us to find out if CNC machining is right for your project and explore some of the key benefits and challenges of the process:

| Excellent mechanical properties | CNC machining can be employed to create parts with a range of mechanical properties. |

| Established technology | CNC machining doesn’t require the creation of expensive molds, meaning that production can begin sooner than other manufacturing processes. |

| Wide variety of materials | Machine parts in an array of metals and plastics to meet your project’s requirements. |

| Scalability | The CNC machining process enables manufacturers to scale from prototyping to volume production smoothly. |

| Speed | From rapid prototyping to high volume production, CNC machining is highly automated, and enables fast, efficient production. |

| Consistency and precision | With multiple machines working from the same design, the CNC process delivers high levels of consistency and precision across every project. |

| Unused material | The CNC machining process creates unused waste as it removes material from the workpiece. |

| Limited part geometry | CNC parts may be limited by the geometric capabilities of the machine in which they are being manufactured. |

| Higher initial cost | The CNC machining process involves higher initial costs than other manufacturing processes in order to meet design and tooling requirements. |

Why choose Fast Radius for CNC machining?

Quality manufacturing

We manufacture CNC machined parts to meet your quality needs, and can achieve precise tolerances across our 3-axis, 5-axis, and turning processes.

Industry expertise

Access a team of manufacturing and engineering experts that care about your project and will work with you from concept to fulfillment.

Innovation and agility

Our CNC machining services are powered by innovation: the World Economic Forum has recognized Fast Radius as one of the most innovative factories in the world.

Global reach

A global network of production partners and logistics hubs ensures the fastest possible shipping times. Our partnership with UPS gives us the power to move products around the world with ease.

The factory of the future

The Fast Radius Cloud Manufacturing Platform™ combines digital design technology with the expertise of our team to make your project possible.

Ordering your CNC machined parts in Maryland

Step 1

Sign up

Create a Fast Radius account, upload your CAD file, and choose your CNC machining service.

Step 2

Apply insight

Apply automated manufacturing insight to optimize your project for quality and cost.

Step 3

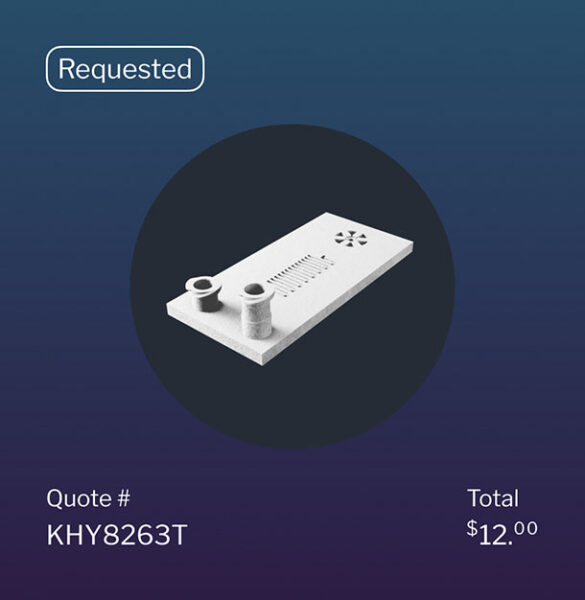

Receive your quote

Receive an instant quote, reflecting your design specifications and your finishing and inspection requirements.

Step 4

Place your order

Place your order to begin production. When it’s ready, we’ll let you know that we’re packaging and shipping your parts.

Get an instant quote for your CNC machined parts

Looking for CNC machining services near you?

Our CNC machining services are available in every part

of the United States.

CNC machining case studies

Fast Radius CNC machining services help companies around the world solve manufacturing challenges every day. Explore our CNC machining projects to learn more about the ways that our work creates an impact.

Automotive

Making riding in style possible

Curtiss had big plans to make an electric motorcycle unlike anything the world had ever seen. Fast Radius had comprehensive CNC solutions to make that goal possible.

Fast Radius manufacturing capabilities

Fast Radius manufacturing solutions, including CNC machining, serve a spectrum of manufacturing needs and are used across the industrial landscape. Explore our manufacturing capabilities:

Back

Back