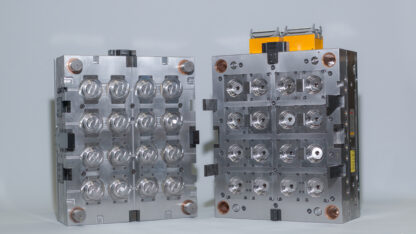

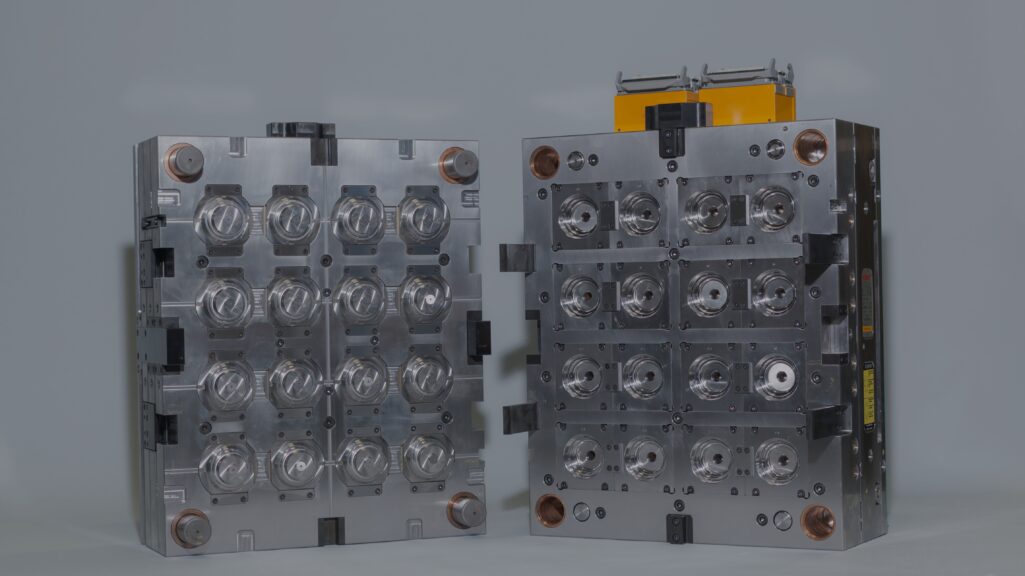

Multi-cavity/family mold service

Create more injection molded parts, faster, with our multi-cavity and family mold service.

What is a multi-cavity or family mold?

The injection molding process begins with the creation of a mold which can shape molten thermoplastic into a desired final part. Some injection molding projects only require the creation of a single cavity mold but if a large quantity of identical or similar parts are needed, within a limited timeframe, it often makes more sense to create a multi-cavity mold or a family mold for production.

Both multi-cavity molds and family molds enable the production of multiple injection molded parts from a single shot of thermoplastic. Multi-cavity molds are used for large quantity production of a single unique part design, while family molds are used in the production of parts with very similar shapes and sizes.

Unlock the potential of your injection molding project: use our multi-cavity and family mold services to boost production speed and efficiency and get your part orders faster. Upload your CAD file to our Cloud Manufacturing Platform™ and work with expert engineers to optimize your design. When you’re ready to begin production, we’ll manufacture your parts, apply any requested inspections, and ship to your location.

For more on-demand manufacturing options, browse our injection molding services, including our insert molding and overmolding services.

Design considerations

Enhance your multi-cavity or family mold injection molding project with the following design considerations:

| Maximum part size | 800 x 800 x 400 mm 31.5 x 31.5 x 15.7 in Maximum part size applies to quantity 1 parts only. Maximum part size is reduced for subsequent quantities. |

| Minimum part size | 1 x 1 x 1 mm 0.04 x 0.04 x 0.04 in |

| Tolerance | Best achievable tolerance: ±0.001″ (0.025mm) Standard: ±0.005″ (0.127mm) For larger part tolerances please contact a Fast Radius engineer |

| Lead time | As low as 2 weeks for T1 samples After T1 sample approval, lead time for < 10,000 parts is as low as 1 week |

| Tool validation | Standard process is to produce a small set of T1 samples for approval before initiating full production |

| Maximum press size | 1600T |

| Minimum order size | 100 parts and $5000 |

| Set-up fee | $500 per mold per order (applies to sample runs after initial T1 samples or engineering changes) |

| Multiple identical cavities or family of parts machined into a single tool |

| Allows for more parts to be produced per shot, minimizing unit costs |

| Production tooling | Steel tool with shot life up to 1M shots Ability to integrate side-pulls or cam-actions Typically machined in 3 weeks |

| Rapid injection molding | Molds with steel cavity and core with a shot life of 5,000-10,000 shots Typically machined in 2 weeks |

| Insert molding | Inserts are placed into the mold and molding occurs around them to extend tool life for critical features Allows for inserts such as helicoils to be molded in your design |

| Overmolding | Premade parts are placed into the mold and molded over |

| Most common materials | Other supported materials | Additives and fiber |

|---|---|---|

| Acrylonitrile Butadiene Styrene (ABS) | Nylon (PA 6, PA66, PA12) | UV absorbers |

| Polyethylene (PE) | Polycarbonate/Acrylonitrile Butadiene Styrene (PC/ABS) | Flame retardants |

| Polypropylene (PP) | Polyurethane (PU) | Plasticizers |

| Polycarbonate (PC) | Polymethyl Methacrylate (PMMA/Acrylic) | Colorants |

| High Density Polyethylene (HDPE) | Glass fibers | |

| Low Density Polyethylene (LDPE) | ||

| Polystyrene (PS) | ||

| PEEK | ||

| POM (Acetal/Delrin) | ||

| Polyethylene Terephthalate (PET) | ||

| Thermoplastic Elastomer (TPE) | ||

| Thermoplastic Vulcanizate (TPV) | ||

| Polyetherimide (PEI) | ||

| Polysulfone (PSU) | ||

| Inquire for additional options |

| Metal | Plastic |

|---|---|

| Brass | Polypropylene (PP) |

| Stainless steel | Polyamide (Nylon) |

| Aluminum 6061 | Acrylonitrile Butadiene Styrene (ABS) |

| Aluminum 7075 |

Injection molding finishing and

post-processing

We can apply a range of injection molding finishing and post-processing options to multi-cavity and family molded parts:

| Colors | Finishing and post-processing options |

|---|---|

| Pantone color matching | Standard SPI finishes (A2-D3) |

| RAL color matching | Mold-tech textures also available |

| Pad printing | |

| Inserts (e.g. heat stake inserts) | |

| Light assembly | |

| Protective packaging / film |

Get an instant quote for your multi-cavity or family mold project

Create a Fast Radius account for rapid quotes on injection molded parts.

Why choose a multi-cavity or family mold?

Multi-cavity and family molds offer the following key benefits and challenges:

Benefits

Benefits

- Enables manufacturers to create more parts

- Increases the speed of production

- Lowers cost-per-unit over time

- Better suited to higher volume production needs

Challenges

Challenges

- More substantial upfront investment than single cavity molds

- Requires longer lead times than single cavity

- Increases maintenance costs and the risk of molding errors

Multi-cavity and family mold applications

From functional prototypes to low volume production runs, the industrial applications of multi-cavity and family molds include:

Higher volume production

Enable higher volume injection molding production capacity.

Speed and efficiency

Reduce lead times and take your injection molded parts to market faster.

Fast Radius manufacturing solutions

Businesses across the world use Fast Radius manufacturing solutions. Learn more about our manufacturing capabilities:

3D printing

Fast, scalable, and cost-effective 3D printing technology for a variety of industrial applications.

CNC machining

Automated CNC turning and 3-axis and 5-axis milling, using rotating drills, end mills, and lathes.

Back

Back