Cast urethane parts

Create high quality plastic parts with speed, precision, and minimal tooling requirements

Order custom urethane parts

Cast urethane parts can be produced quickly and cost-effectively while achieving complex geometries and surface detail. During the casting process, urethane resin is poured into a silicone mold and then placed in a heated vacuum chamber to cure. The end result is a precise replica of the master part.

Order your cast urethane parts from Fast Radius quickly and easily: upload a CAD file to the Fast Radius Cloud Manufacturing Platform™, optimize your project with our expert engineers, and then move to production for delivery on demand.

To learn more about our manufacturing capabilities, explore our full urethane casting service.

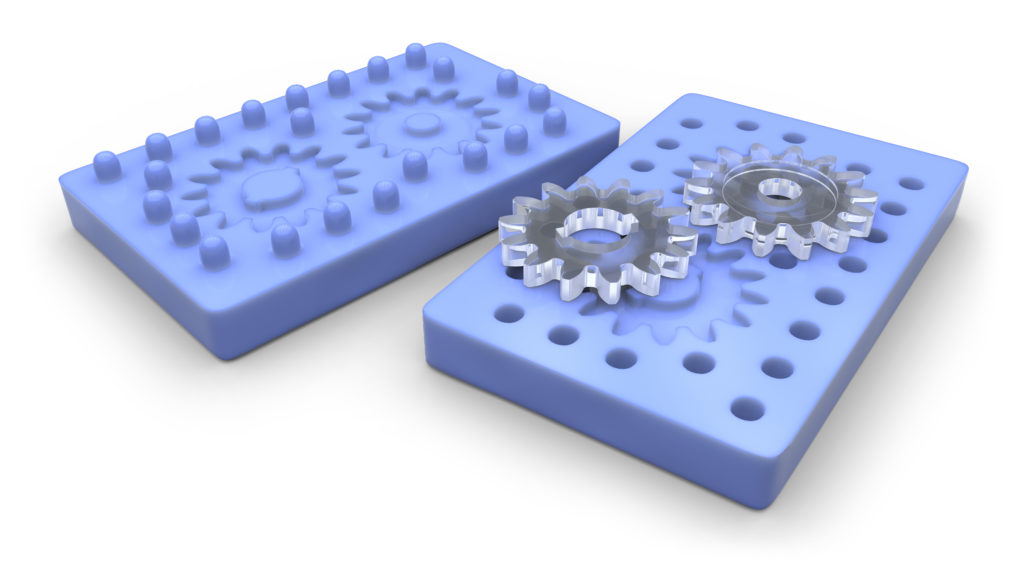

Our urethane casting process

A silicone mold is created around a master pattern part which may be 3D printed or CNC machined.

The silicone mold is filled with urethane casting resin and placed in a heated vacuum chamber until the resin is cured.

Once cured, the part is ejected from the mold as a 1:1 scale replica of the master pattern. If necessary, the part is ready for finishing and post-processing.

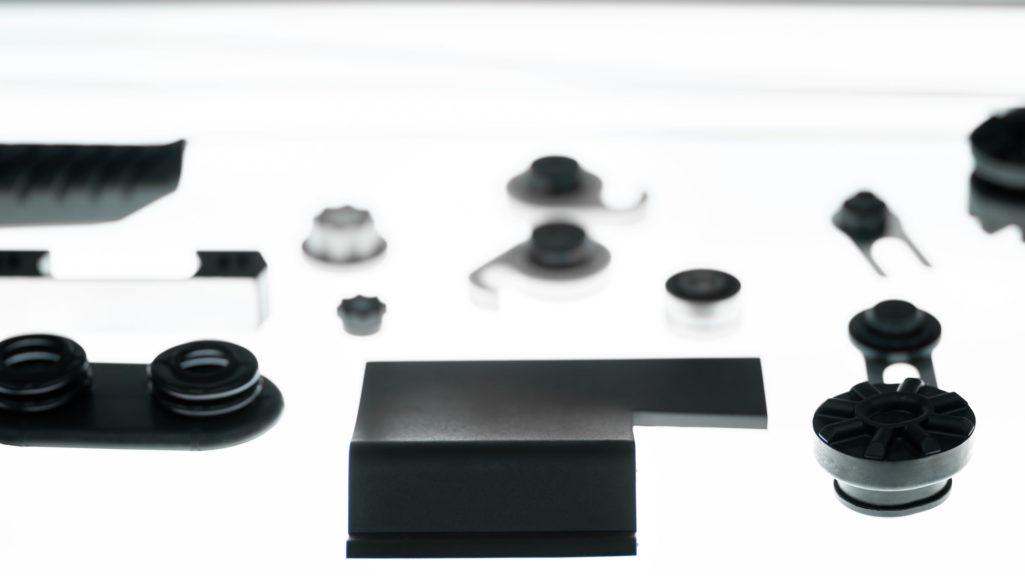

Urethane casting applications

Urethane parts are useful in a number of industrial applications, including:

Prototyping

The urethane casting process enables manufacturers to prototype varieties of size, strength, material, and color quickly and cost-effectively, before moving to production.

Aerospace and automotive

The flexibility of the urethane casting process makes it ideal for bridge tooling between the prototyping and production stages of the manufacturing process.

Joints casting

Urethane casting is ideal for manufacturing strong, durable mechanical joints with overlapping features.

Logos

The precision and consistency of urethane casting makes it particularly effective in the production of 3D logos and letters.

Why choose urethane casting for your parts?

Turnaround times

The speed of the urethane casting process means that you can move from prototyping to production quickly, with lead times as low as 7 days for first articles, and 2 weeks for remaining parts.

Low volume production

After initial tooling, the urethane casting process allows manufacturers to scale easily from cost-effective prototyping or single part production, to low volume production.

Customization

Cast urethane parts can be manufactured with complex geometries and detail. The production process offers a range of finishing and post-processing options for greater customization potential.

Ease of alteration

The speed and flexibility of the urethane casting process means that manufacturers can implement alterations to their parts quickly and efficiently, with minimal tooling and labor requirements.

Get a quote for your cast urethane parts

Create a Fast Radius account for rapid quotes on parts production.

Design considerations

Optimize your custom urethane parts with the following design considerations, and browse production materials, finishing, and post-processing options.

| Maximum part size | 914.4 x 914.4 x 1828.8 mm 36.0 x 36.0 x 72.0 in Note: Ability to break parts up into multiple segments to create an even larger assembly |

| Minimum feature size | 0.635 mm for features 0.025 in for features 1.016 mm wall thickness 0.040 in wall thickness |

| Best achievable tolerance | 0.005 in (0.127 mm) for first inch, followed by 0.003 in (0.0762 mm) per lineal inch cumulatively |

| Lead time | As low as 7 days for first articles (FA) After FA approval, as low as 2 weeks for remaining parts |

| Standard | High performance | FDA | Clear |

|---|---|---|---|

| ABS-like (80D) | Nylon-Delrin like (84D) | ABS-like (80A) | Optical Clear (80D, water clear) |

| PE-like (65D) | ABS-High Impact (78D) | ABS-High Strength (85A) | PC-like (84D, haze/pale yellow) |

| PC-like (84D) | High Impact FR (UL-94V0) (85D) | Hi Impact Class VI (85D) | |

| PP-like (70D) | Hi Temp (84D) | ||

| 12 Sec burn (78D) |

| Part finishes |

|---|

| Smooth |

| Satin |

| Glossy / polish |

| Custom finishing available |

| Elastomers | Clear Elastomers | Silicones | Medical silicones |

|---|---|---|---|

| Standard elastomers (15A-94A) | Clear elastomer (45A, water clear) | 15A | 38A |

| High performance elastomers (15A-90A) | Clear elastomer (65A, water clear) | 25A | |

| Clear elastomer (70A, water clear) | 35A | ||

| Clear elastomer (90A, water clear) | 40A | ||

| 42A | |||

| 50A | |||

| 53A | |||

| 60A | |||

| 75A |

| Part finishes |

|---|

| Smooth |

| Satin |

| Glossy / polish |

| Custom finishing available |

Why choose Fast Radius for urethane casting?

The factory of the future

The Fast Radius Cloud Manufacturing Platform™ combines digital design technology with cutting-edge expertise to make your projects possible.

Fast Radius manufacturing capabilities

Fast Radius manufacturing solutions serve the needs of businesses across the industrial landscape. Explore our capabilities:

3D printing

Fast, scalable, and cost-effective 3D printing technology for a variety of industrial applications.

CNC machining

Automated CNC turning and 3-axis and 5-axis milling, using rotating drills, end mills, and lathes.

Back

Back