Making emergency medical care possible

TacMed Solutions needed a manufacturing partner for critical parts due to rising order quantities and the war in Ukraine. With an agile supply chain and rapid turnaround, Fast Radius helped them increase production so that TacMed could fulfill demand and deliver tourniquets to Ukraine’s war effort.

The Challenge

Rapidly scaling production for emergency medical tools

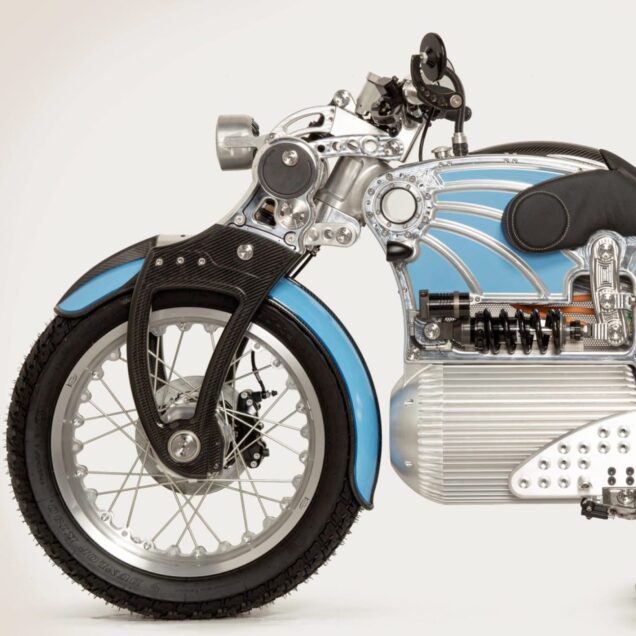

TacMed, a leading medical equipment company focused on increasing survivability, found their existing production and supply chain was unable to keep up with growing demand for their SOF® Tourniquet. Fast Radius rapidly moved to production, enabling TacMed to distribute critical equipment.

TacMed first came to Fast Radius for CNC machining support to scale production of the aluminum handle on their SOF® Tourniquet because their existing manufacturer was unable to keep up. Fast Radius adapted manufacturing workflows to meet TacMed’s urgent requirements, developing specialized inspection plans and accelerating production to meet TacMed’s needs. This way, Fast Radius delivered 100,000 parts to TacMed in just 30 days, meeting their desired timeline while reducing costs.

When Russia attacked Ukraine, the global need surged for TacMed’s tourniquets, which soldiers and emergency responders carry to improve survivability in crisis situations. Shipments of TacMed’s SOF® Tourniquets have gone into the hands of Ukrainian forces, and while the company’s demand naturally skyrocketed from selling to allied partners supporting Ukraine, they also prioritized manufacturing tourniquets to donate to the war effort through Samaritan’s Purse, Afya, and the Ukrainian American Foundation.

In total, TacMed has provided more than 50,000 tourniquets to the Ukrainian war effort as of May 2022, with plans to grow that number into the hundreds of thousands in summer 2022 if needed. These ambitious plans require consistent manufacturing for high part volumes and a steady supply chain.

When the war in Ukraine started, we weren’t going to let supply chain issues get in our way. Having Fast Radius as a communicative, transparent manufacturing partner has helped us move quickly to jumpstart production and deliver lifesaving supplies to those on the front lines who need them most.

Making it possible

Building a reliable supply chain for lifesaving parts

1. Rapid ramp to production

Accelerated production was critical for TacMed, whose existing suppliers could not keep up with necessary production timelines. Fast Radius adjusted manufacturing processes, provided early part and post-processing samples, and delivered the first shipment of 100,000 parts within 30 days.

2. Close supplier relationships

Fast Radius’ global supplier network offers customers access to preferred pricing and fast lead times. Fast Radius’ strong, established supplier relationship allowed for negotiation of a more competitive price for TacMed’s parts.

3. Dedicated supply chain team

With global supply chains in disarray, dedicated logistics support is critical. Fast Radius’ internal supply chain team vetted suppliers, ensured parts were shipped on time, and led the import process to deliver the parts TacMed needed, when they needed them.

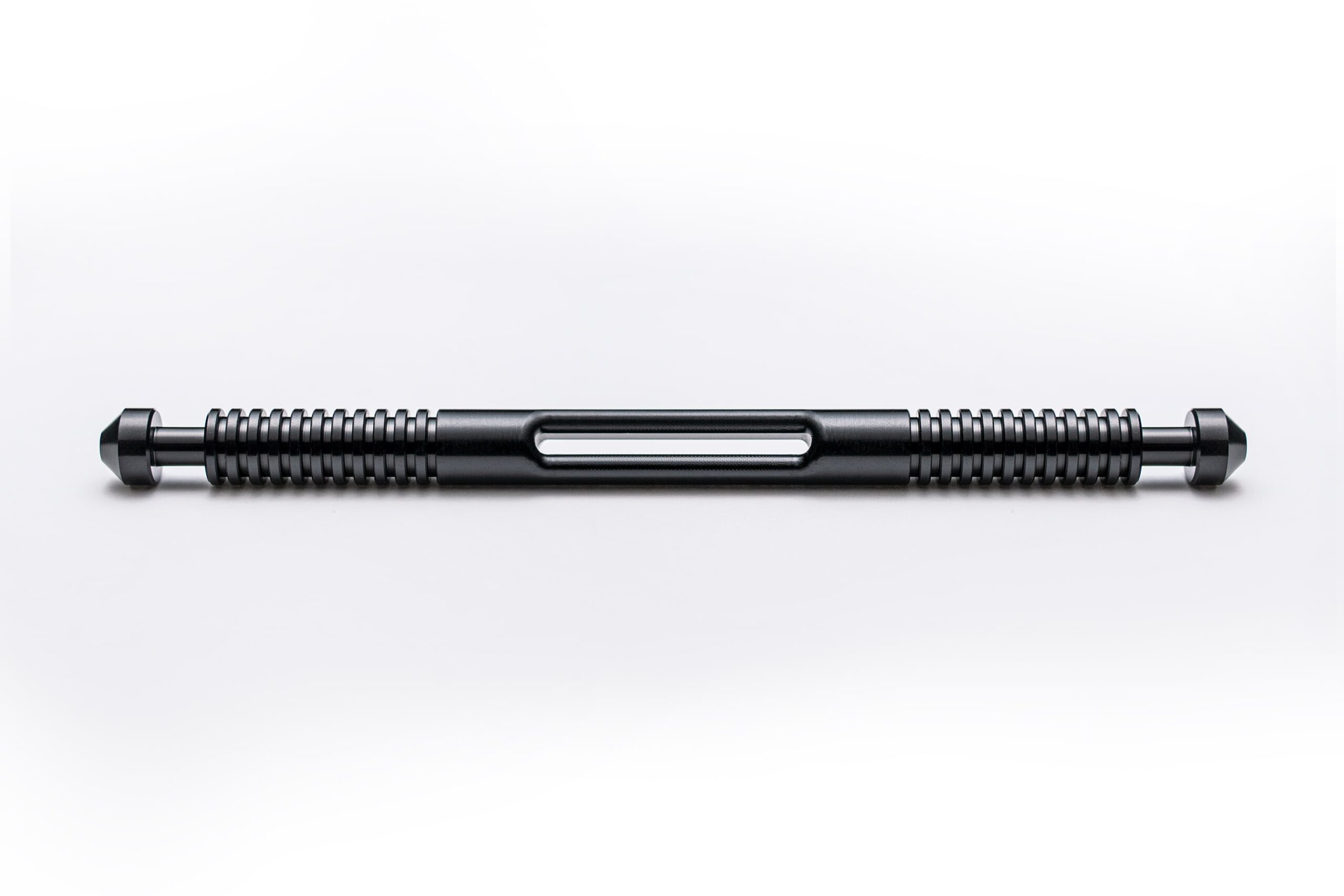

4. Agile inspection plans

The CNC machined tourniquet handle requires a mixture of 2-axis lathe and 4-axis milling to manufacture and includes tight tolerances that require precision. Fast Radius customized the first article inspection process, starting with electronic delivery, to ensure quality while fulfilling TacMed’s needs.

Gallery

the results

Scaled machining on an accelerated timeline

30

days

From first purchase order to fulfillment

175,000+

parts

Manufactured in a 6-week timeframe

50,000+

tourniquets

Delivered by TacMed to the Ukrainian war effort

Back

Back