Making more precise medical treatment possible

Axial3D needed to find a partner to produce its surgical models, at scale, with the speed required by surgeons. Fast Radius made repeatable, precise production possible with additive manufacturing to deliver models within just 72 hours.

THE CHALLENGE

Transforming how surgeons prepare for complex operations

When Axial3D wanted to expand into North America, they needed a partner who could produce their models with the same clinical specifications, at high volumes, and in line with the speed required by today’s medical community.

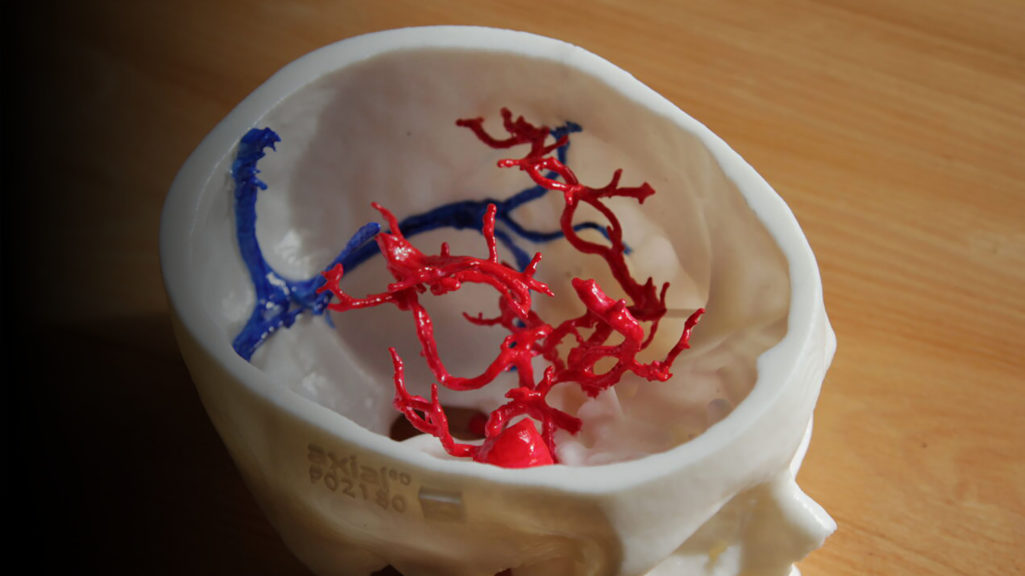

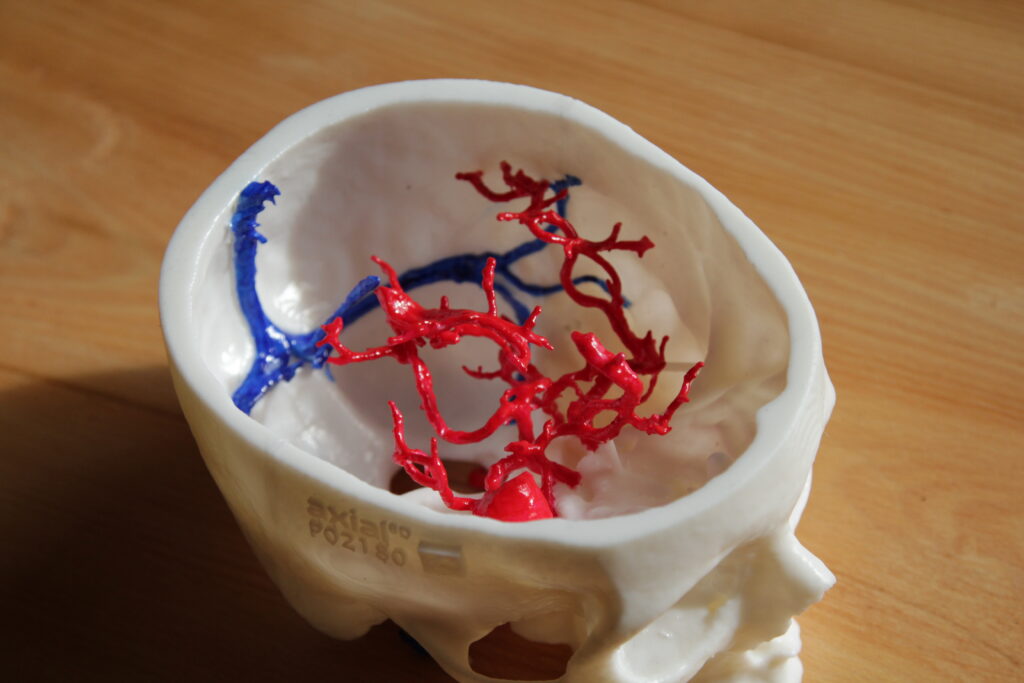

Axial3D is a medical technology firm based in Northern Ireland working to transform surgical planning through the use of patient-specific 3D anatomical models. Surgeons and medical professionals send patient files — like CT scans and MRIs — to Axial3D, who use their cloud-hosted software, driven by state-of-the-art algorithms, to convert the scanned images into a ready-for-print file in under one hour.

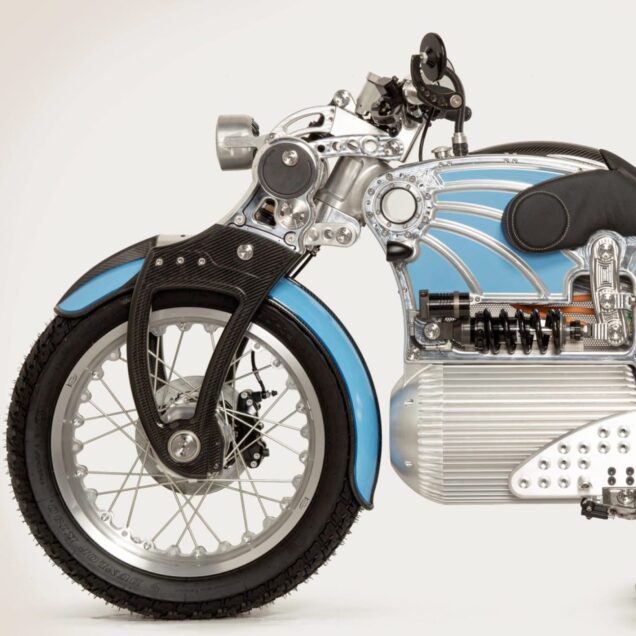

The 3D file is printed and delivered to the surgeons, who then use the model to prepare cardiovascular, orthopaedic, trauma, neurological, and other invasive surgeries. This approach to surgical planning leads to shorter pre-operative cycles, more efficient surgeries, and faster recovery times for patients.

Axial3D identified Fast Radius as the perfect innovation partner because of their technology-agnostic approach to manufacturing and ability to quickly reach customers across the United States.

The partnership between Fast Radius and Axial3D comes at a critical time for healthcare institutions. We are now able to support surgeons and hospitals in the US who are desperately trying to minimize the impact of COVID-19 on their business as they endeavor to rapidly address the elective surgery backlog.

MAKING IT POSSIBLE

Faster, more precise surgical planning

1. Precision accuracy

The models Axial3D makes need to meet strict requirements; any breaks, crevices, cavities, and other minute details must be accurate to the micro-millimeter, providing doctors with otherwise unavailable patient insights. Rather than relying on 2D imaging to work out the spatial distance between key areas of anatomy, surgeons find it faster and more reliable to request a 3D model created from their patient scans. Fast Radius’s array of printer technologies meets Axial3D’s ultimate requirements, ensuring hyper-accuracy and a full spectrum of color options to bring unprecedented detail to surgical planning.

2. The right technology

Extensive additive manufacturing capabilities — from Carbon Digital Light Synthesis (DLS) to HP MultiJet Fusion (MJF) and Formlabs SLA — meant Axial3D could come to Fast Radius to find the best solution for its customers’ wide spectrum of needs. When supplying models across a number of healthcare disciplines, it’s not just accuracy that matters; form factor, material, and finishing options are critical to a successful model. Fast Radius has the ability to print the pliable hearts preferred by cardiovascular surgeons, colorful knees used by orthopedic surgeons, and translucent kidneys critical to preoperative renal surgery planning.

3. Powerful insights

Fifty percent of surgeons who use Axial3D’s models claim to have changed their plans for surgery as a result. Where 2D scans fail to catch subtleties like hidden crevices and small growths, Axial3D’s models printed by Fast Radius bring them to life, empowering surgeons with greater confidence when planning complex surgeries. In the case of one patient — a newborn baby with a double outlet right ventricle (DORV) and ventricular septal defect (VSD) — the surgeon found it almost impossible to identify the scale of the problem using 2D images alone; they couldn’t capture the angles and precise location of the VSD. But with one of Axial3D’s models on his desk two days later, he identified a second VSD and defined a plan to correct the two VSDs with one surgery, removing the need for a secondary procedure entirely.

4. Flexible fulfillment

Fast Radius can print and fulfill model orders in just 72 hours, enabling the speed required for pre-operative planning. Surgeons send their patient data to Axial3D, who then populate the print file and send directly to Fast Radius for production. Files are printed on-demand at Fast Radius’s factory in Chicago, and shipped in under three days to surgeons through a fulfillment partnership with UPS. Together, Fast Radius and Axial3D will print anatomical models to support the planning for hundreds of complex surgeries each month.

THE RESULTS

Fast Radius and Axial3D are making the surgical decision-making process faster and more precise.

50%

of surgeons change their pre-operative plans when using an Axial3D model

62 minutes

saved on average per case when a 3D model is used in planning for a procedure

16%

reduction in recovery times when a patient-specific model is used in treatment

Gallery

Back

Back