Making visionary art possible

Navillus Woodworks was tasked with the production of an outdoor art installation that could weather Chicago’s harsh climate. Fast Radius’s advanced manufacturing expertise helped make it possible.

the challenge

Bringing an artistic vision to life with advanced manufacturing

Navillus Woodworks needed custom molds for an art installation made outside the realm of traditional manufacturing.

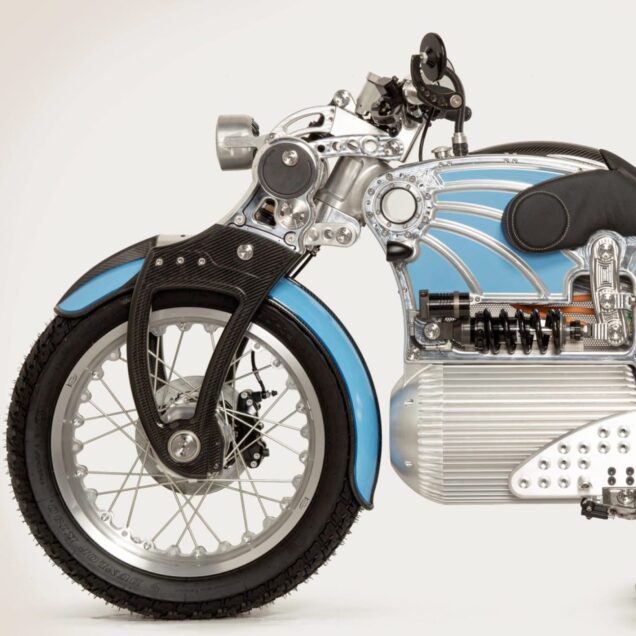

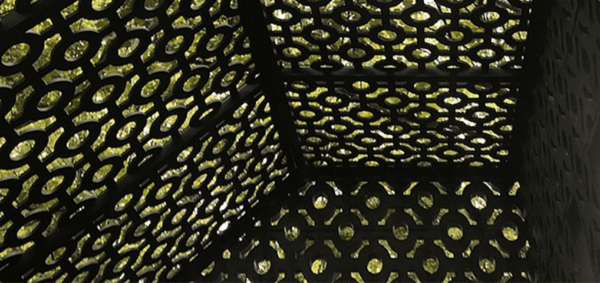

Artist Edra Soto was commissioned to build an outdoor installation in Chicago’s iconic Millennium Park, where she envisioned creating a 10-foot-tall structure that could withstand Chicago’s harsh climate. She partnered with Navillus Woodworks to construct the installation, which would be composed of more than 400 custom-cast concrete blocks. Soto’s stunning Screenhouse installation is a rich immersive experience that evokes decorative screens (known as rejas and quiebrasoles in Soto’s native Puerto Rico) to create a free-standing social structure that challenges the distinction between public and private spaces.

Though the Navillus team were experts in traditional manufacturing methods, they knew little about making molds for casting Ductal® concrete material. The center support structures in the mold proved especially difficult. The Navillus team had unsuccessfully tried several methods to craft the center pillars, including CNC, when they turned to the Fast Radius team.

The guidance we got from the Fast Radius team proved invaluable. Together we were able to make mold components that met our mechanical specifications, budget and timeline. The results speak for themselves.

MAKING IT POSSIBLE

Rapid iteration and engineering expertise

1. Manufacturing expertise

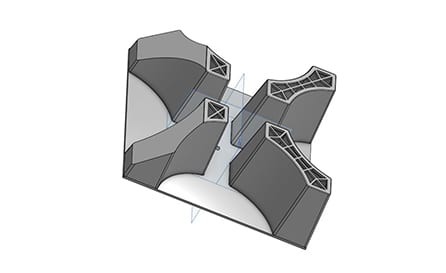

Fast Radius engineers determined that the parts could be made of Polyamide 12 (PA 12) printed on HP Multi Jet Fusion (MJF) equipment. MJF produces fully densified, near-isotropic PA 12 parts, meaning the material retains its physical properties regardless of direction. Fast Radius knew this method would produce parts that stood up to the concrete casting process without compromising the structural integrity of the mold. MJF was also well-suited to the low-volume production Navillus needed because it doesn’t require any costly machining or mold creation.

2. Rapid iteration

The Navillus team tried machining the molds with a CNC router, but the process was time-consuming and expensive. Mistakes proved costly; a machining or routing issue meant starting the whole process over. Plus, the Corian parts they machined were too heavy for the mold. With HP MJF technology, Navillus and Fast Radius printed and tested three design iterations in a matter of only 10 weeks before settling on the final design. And because MJF parts are suitable for end-use, Navillus tried out the prototypes in the context of the rest of the mold. The team settled on a design that was thin, lightweight and suited to concrete casting.

3. Application engineering

Fast Radius’ team of expert industrial designers and engineers made rapid iteration possible through their expertise in designing for additive manufacturing (DfAM). In the case of Screenhouse, Fast Radius and Navillus discovered that MJF technology could produce light, hollow structures without sacrificing the mechanical strength needed to support concrete. Fast Radius further saved material cost for Navillus by optimizing the design to fit multiple parts in each build. Fast Radius ultimately produced nine PA 12 parts for each block mold and supplied Navillus with 21 sets of parts. It took three months from the moment Navillus met Fast Radius until they had parts in hand.

4. A striking installation

The Screenhouse installation went up in Millennium Park’s Boeing Gallery North (near the iconic sculpture Cloud Gate, or “The Bean”) in October of 2019, and the finished product reflected Soto’s vision. It casts a striking silhouette and will weather an entire year in Chicago.

“Our mission is to make new things possible to advance the human condition, and I can think of no better way to serve that mission than helping bring Edra Soto’s beautiful design to life in our city’s famed Millennium Park,” said Fast Radius Chief Executive Officer Lou Rassey. “This project shows the potential of additively manufactured molds to redefine construction project design.”

Gallery

the results

An iconic art installation made with the support of advanced manufacturing

400

custom-cast concrete blocks

3

months

21

sets of parts

Back

Back