Making a trailblazing motorcycle possible

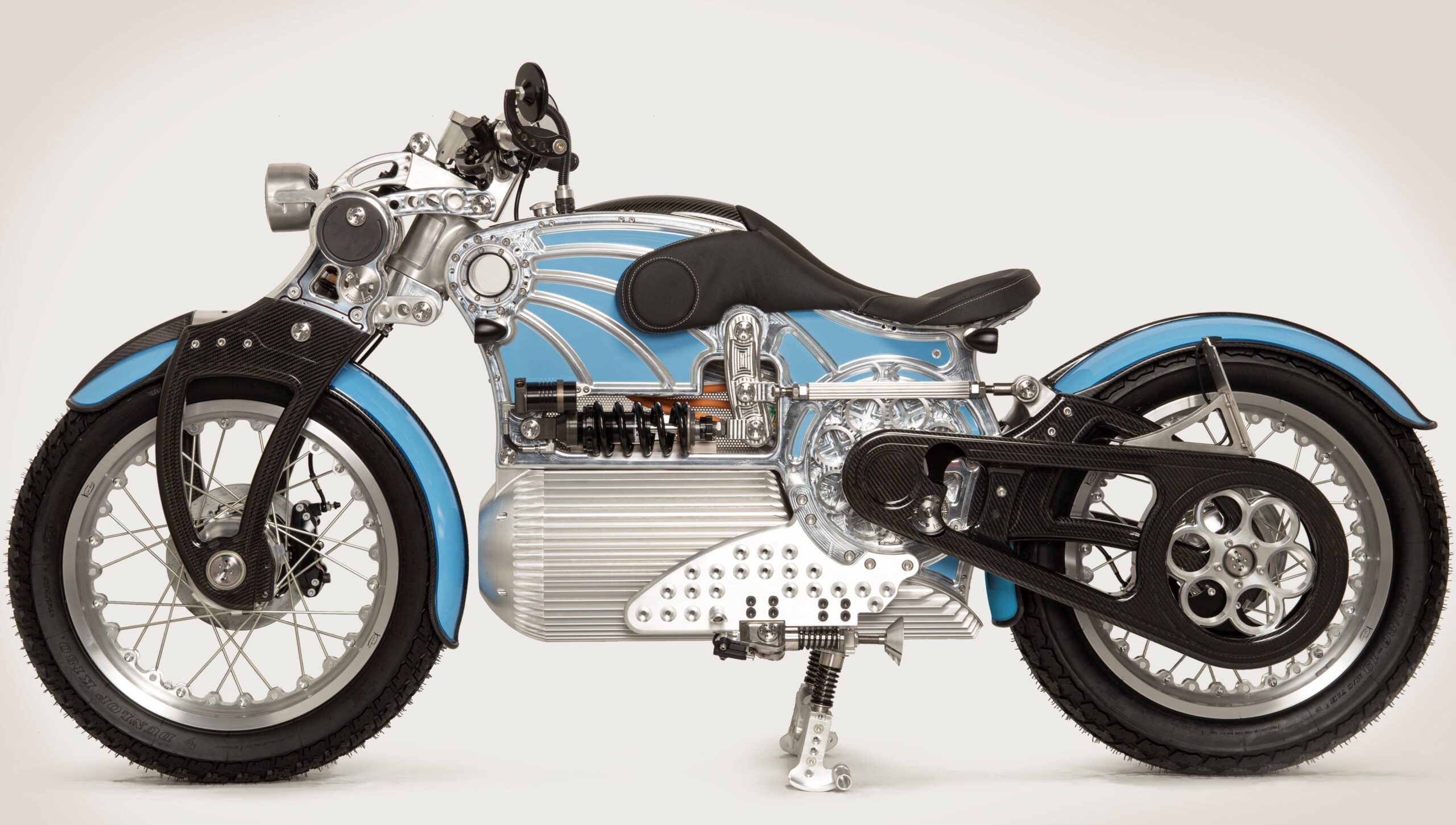

Curtiss reinvented the electric vehicle category with the Curtiss One, a luxury electric motorcycle with unparalleled performance and aesthetic appeal. Fast Radius provided innovative production and fulfillment solutions that allowed Curtiss to bring their vision to the world.

THE CHALLENGE

Producing a design-driven luxury electric motorcycle with the flexibility of on-demand manufacturing

Curtiss envisioned a revolutionary electric motorcycle, but struggled to find a manufacturing partner up to the challenge.

Curtiss designed an electric motorcycle unlike anything the world had ever seen, and they needed to unveil a prototype quickly. Fast Radius made their vision possible with multi-process manufacturing solutions.

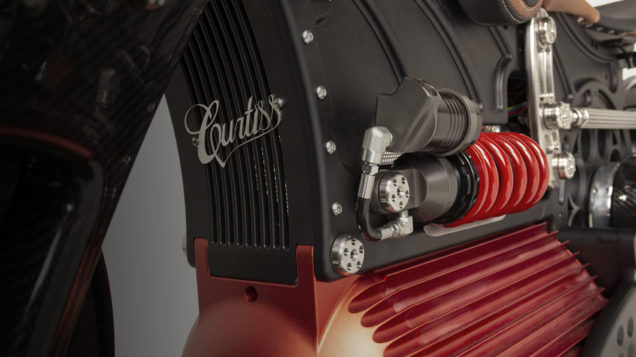

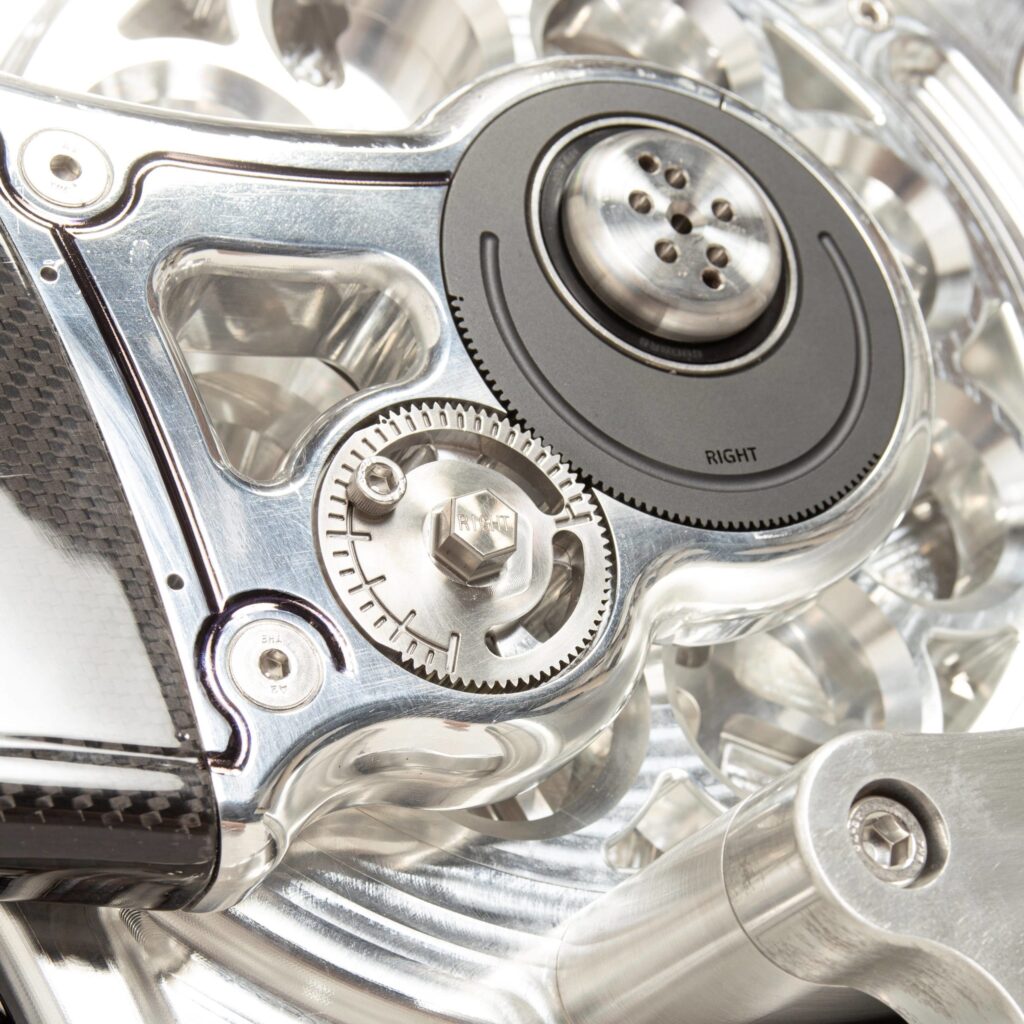

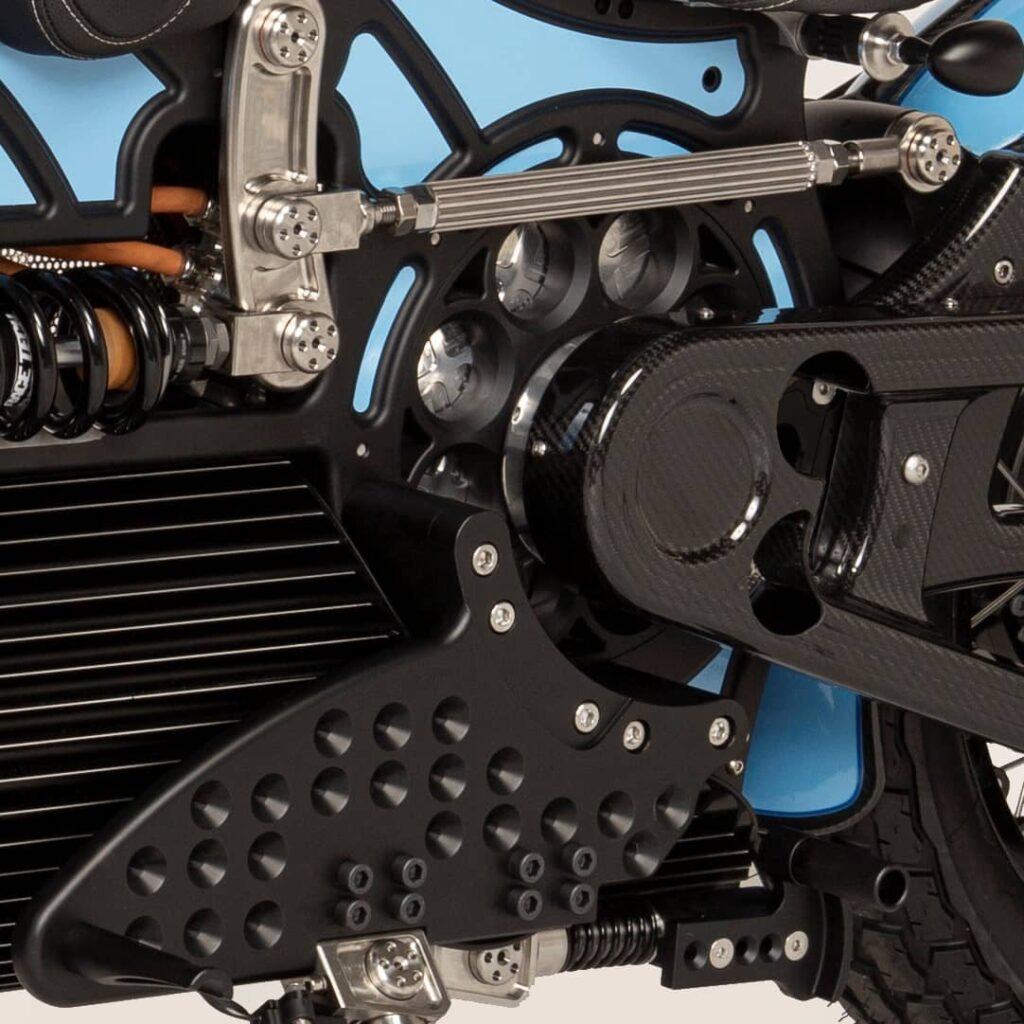

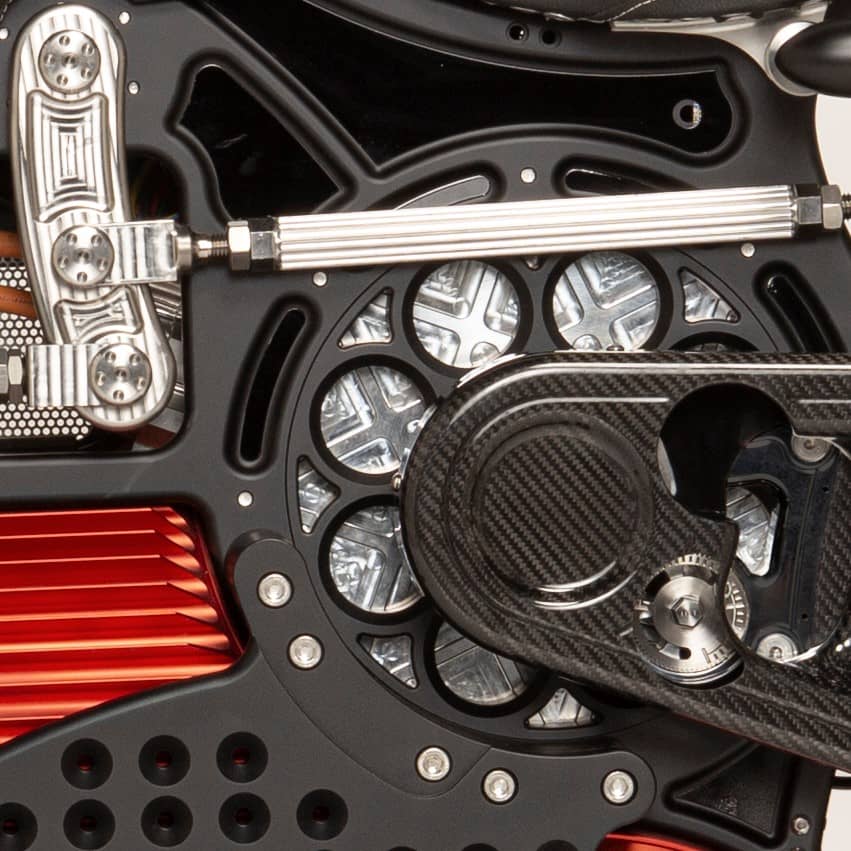

The Zeus 8 is an exceptionally beautiful bike. It has a sweeping chromoly frame and eight banks of sleek, visible battery cylinders. However beautiful, these large, complex parts proved difficult to manufacture. Curtiss’ CNC suppliers quoted long lead times and had trouble delivering on the uncompromising design and quality requirements. With the Zeus 8 launch event approaching, Curtiss needed a partner who could get the unique bike into production immediately.

Fast Radius allows our company to seamlessly expand to new models and segments as the market for EV motorcycles grows. With Fast Radius, turning around new designs and prototypes is faster and less expensive than with any other manufacturer. We’re able to outmaneuver large companies and plan for our future without worrying about scaling. We can’t thank Fast Radius enough for their partnership. The quality of the work they’ve done for us is unbelievable.

MAKING IT POSSIBLE

On-demand production and a flexible long-term partnership

1. Long-term production partnership

Fast Radius has a deep understanding of Curtiss’ business that goes beyond making all of Curtiss’ CNC and additive parts. Unlike a typical contract manufacturer, Fast Radius has visibility into the entire production process, making for a seamless ramp from concept to prototype to production.

2. On-demand manufacturing

Curtiss orders parts from Fast Radius as needed, eliminating the logistics and expenses of warehousing. Fast Radius is able to provide the cost efficiencies of large orders without forcing Curtiss to take delivery of all their parts at once. With Fast Radius, Curtiss can access flexible capacity to easily ramp up production as demand increases.

3. Economic efficiency

Fast Radius stuck to Curtiss’ budget, leveraging relationships with trusted production partners to get extremely competitive prices — even on expensive post-processing and anodization. To keep fulfillment costs down, Fast Radius devised strategic shipping solutions and payment terms. Since this is an ongoing project, Curtiss gets Fast Radius’ annual discounts for long-term production.

4. Hands-on project management

No single factory could make all the parts for the Curtiss One, so Fast Radius coordinated production within their global network. Fast Radius handles all project management and quality operations, ensuring Curtiss receives parts made to spec and on schedule. If issues arise — even with overseas suppliers — the Fast Radius project management team finds a solution, usually without having to involve Curtiss at all. On the front end, Fast Radius provides design for manufacturing (DFM) support, ensuring every part will be made correctly the first time.

Gallery

THE RESULTS

A partnership that’s transforming the motorcycle industry

160

parts per bike

90%

BOM made by Fast Radius

1 month

order cycles

Back

Back